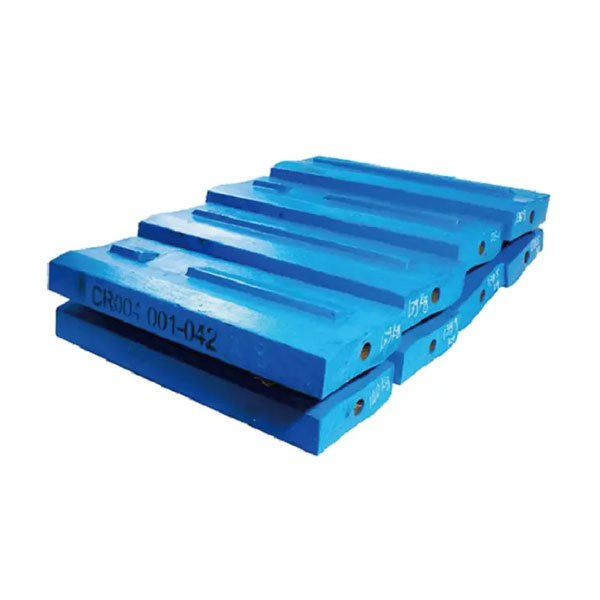

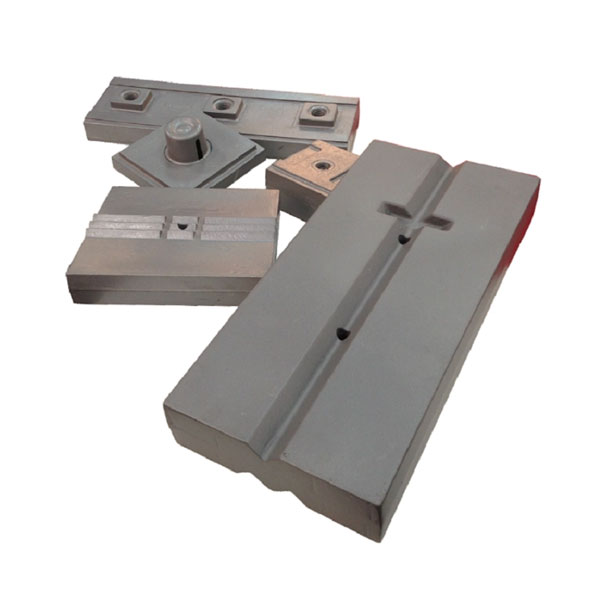

Blow Bar & Impact Plate is manufactured with high chrome white iron steel Cr20, Cr26, Cr28, Cr30 or high chrome with special alloy, which employ the external refining technology effectively reduced the harmful elements, impurity, oxygen and hydrogen harm, greatly enhanced the abrasion resistance and impact toughness of the steel. Using proprietary metamorphic agent for modification treatment, fine grains, improve carbide configuration and distribution, and to improves the abrasion resistance and tenacity. After heat treatment process, the hardness of Blow Bar & Impact Plate can reach to HRC58-65.

MAIN BRANDS SUPPORT:

Metso, Sandvik, Barmac, SVEDALA, Omnicone, EXTEC, Maxtrak, Keestrack, Symons, Hazemag, Cedarapids, Telsmith, McCloskey, Trio, Powerscreen, Kleemann, Terex, Pegson, Kue Ken, Parker, Shanbao, SBM, Zenith, LIMING, MINYU and other famous brands.

MAIN MODELS SUPPORT:

Hazemag 810, 789, 1096, 804, 791, 850A, 795, 797, 811, 857,878, 893, 855, 832, 857, APK40, APK50, APK60.

Metso LT/NP1007, LT/NP1213, LT/NP1315, LT/NP1520

Kleemann MR110, MR130Z, MR130 EVO

Terex Pegson/Terex Powerscreen: XH320&XH320SR, 428, 4242SR, 1412, 500 & 500SR

China Shanbao, SBM, Shanghai Zenith, Shuangquan, Shanghai Longyang, Henan Liming, etc. PF1007, PF1010, PF1214, PF1214V, PF1315, PF1315V, PF1316, PF1318, PF1320 PFW1210II, PFW1214II, PFW1315II, PFW1318II, PFW1210III, PFW1214III, PFW1315II, PFW1318III.

Product Package of Blow Bar & Impact Plate

Steel Pallet. And Customized according to special packing requirement

Application of Blow Bar & Impact Plate Impact crusher is an important equipment in concrete production, road-building and construction waste recycle. Our Blow Bar & Impact Plate are widely used in the mining industry, stone crushing plant, aggregate / quarry plant, construction industry and others.

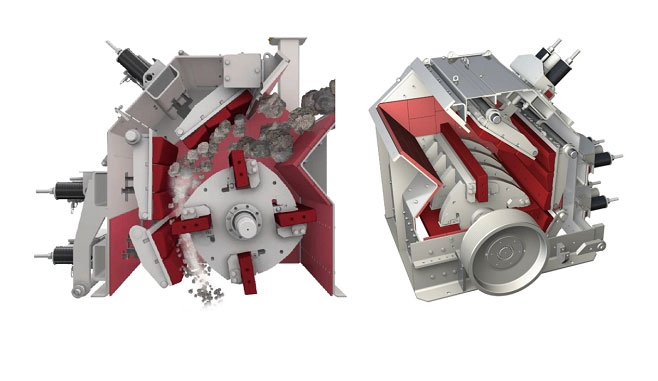

Impact crushers are versatile crushing machines that can be used in any stage of the crushing process. However, the features and capabilities of different impact crusher types vary considerably.

Impact crushers are traditionally classified to two main types: horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers. These different types of impact crushers share the crushing principle, impact, to reduce the material to smaller sizes, but features, capacities and optimal applications are far from each other.

Horizontal shaft impact (HSI) crushers are used in primary, secondary or tertiary crushing stage. HSI crushers reduce the feed material by highly intensive impacts originating in the quick rotational movement of hammers or bars fixed to the rotor. The particles produced are then further fragmentated inside the crusher as they collide against crusher chamber and each other, producing a finer, better-shaped product.

Vertical shaft impact (VSI) crushers, on the other hand, are used in the last stage of the crushing process, especially when its required that the end product has a precise cubical shape.

VSI crusher can be considered a ‘stone pump’ that operates like a centrifugal pump. The material is fed through the center of the rotor, where it is accelerated to high speed before being discharged through openings in the rotor periphery. The material is crushed as it hits of the outer body at high speed and due to rocks colliding against each other.