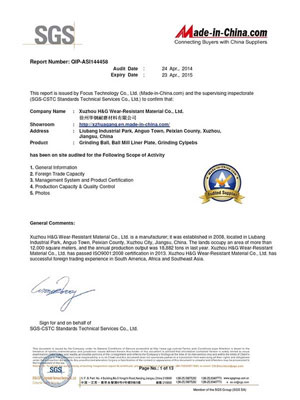

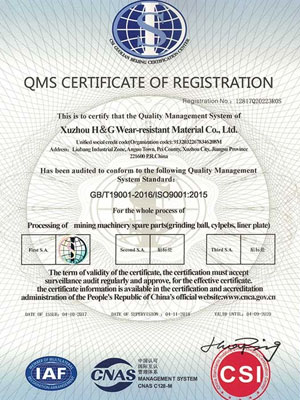

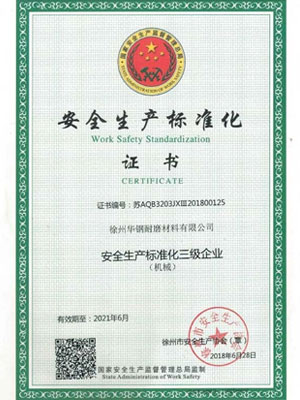

Xuzhou H&G Wear-resistant Material Co., Ltd. was established in 1989, located in Xuzhou, Jiangsu Province. Through more than 30 years' striving, we are becoming one of the leading enterprises in the mining wear parts industry. H&G is devoted to R&D, producing and selling Jaw plates, Mantle and Concave, Mill liners, Grinding Ball/cylpeb ,which are widely used in mining, aggregate, cement and power plants etc.

H&G workshop covers 39,000 square meters, with the standard plant area 21,000 square meters, annual production capacity reaches 30,000 metric tons. Our factory equipped with 2 sand casting spare parts lines, 2 automatic grinding ball lines and one lost foam line for cast iron.

Insisting on the spirit of “Quality Determines Destiny, Positioning Determines Development”, our company is aim to become the leading professional mining wear solution supplier . Welcome to visit us for further cooperation!

H&G Machinery

H&G Machinery (Shanghai) Co.,Ltd is a reliable one-stop supplier with over 10 years experiences in Mining, quarry and cement aggregate machinery spares industry, invested by Xuzhou H&G Wear-resistant Material Co.,Ltd. Our products range from Crusher and mill wear parts, Mineral processing replacement parts, machining spares and construction machine spares.

Insist on the business philosophy of “the right parts for the right application “, H&G machinery has a highly experienced team to help customers choose the right products, reduce costs, increase parts availability and provide an excellent after- sale services.

H&G machinery is quality oriented, focus on Customer’s satisfaction and cost effective, together with our excellent experience in the Mineral processing and cement industry, we will be always benefit and make value for our customers.

Mineral processing:

Crusher Jaw plates, Mantle & Concave, Mill liners, ball mill end cover, bushing, ball mill ring gear, Rubber impellers and diffusers, Polyurethane &Rubber screening mesh, Bolts& Nuts.

Aggregates:

Crusher Jaw plates, Cone Crusher Mantle & Concave, Impact Crusher Blow Bar.

Cement:

Mill liners, Crusher Jaw plates, Stone crusher hammer, Vertical mill parts Stainless screen plate, ball mill end cover, bushing, ball mill ring gear, Mill bolts

Our advantage:

Technical support: We are always ready to asses in details current grinding features of a mill and based on given assessment develop and supply turn key complete set of lining system and grinding media that will reduce running costs.

2.Supply assurance: Timely supply is guaranteed by H&G’s 30,000Tons yearly production capacity on Grinding media, lining and Crusher spare parts.

3.Pre and after sales follow up: Our engineers are ready for On site check of your mineral ground, Design and Make 3D drawing based on size measurement of the lining and crusher part parts, Recommend the right material which is for your application.

4.Sales team: Our team of passionate, talented professionals with cross-industry and cross-discipline experience, bring the level of expertise you need to maintain that winning edge. Our strength is our diversity and our reward is your success