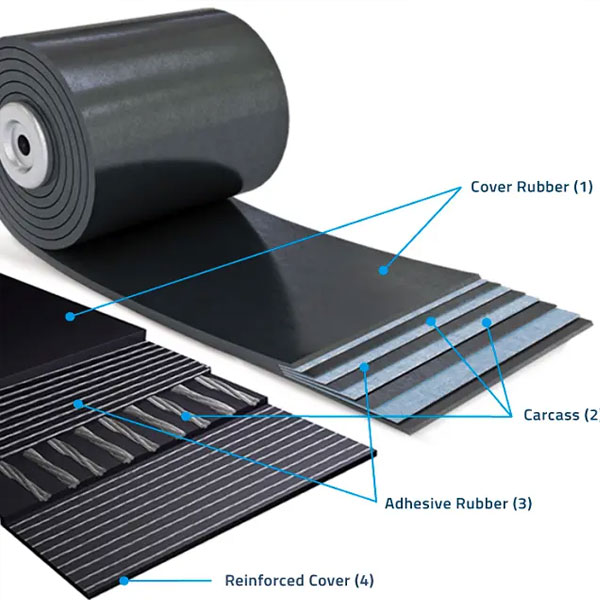

H&G is a famous China Conveyor Belt service and solution provider, the main varieties of conveyor belt are common type(nylon, polyester, steel cord), oil resistance, chemical resistance, heat resistance, cold resistance, fire resistance, anti-tear, chevron conveyor etc., is widely used in mining, cement, steel, electric power, port, metallurgy and other industries.

1. Single/Multi Textile Conveyor Belt

Fabric compositions

Polyester/polyamide(Nylon)------------------------EP

Terylene/cotton-------------------------------------TC

Polyamide(Nylon)/polyamide(Nylon)--------------NN

Polyester/polyamide/polyamide-------------------EPP(SW-straight warp)

Cotton/cotton---------------------------------------CC

Monofilament/polyester----------------------------XE

Weave: from one to six layers

Plain weave,CFW,Rib weave,Broken twill weave

Tensile strength:100kN/m/ply-800kN/m/ply

Width:300mm-2500mm

Thickness of cover rubber:1.5mm-30mm

Nylon is one of the best quality synthetic fiber the rubber industry use nowadays. The nylon canvas is woven by nylon fiber both in warp and in weft. It is the most widely used fabric in rubber industry, and its outstanding merits are its high abrasion resistance, high tensile strength and good fatigue resistance. Conveyor belts with nylon canvas inside have the characteristics of thin belt body, high tensile strength, good shock resistance, good trough ability, high adhesion between plies, splendid flexibility and long working life. Nylon conveyor belts are suitable for medium,long一distance and heavy-load transportation of materials, widely used in mining.metallurgical industry and architectural industry, ports and so on.

EP conveyor belt

The polyester conveyor belt is also called EP conveying belt. Its framework material is the polyester canvas interwoven with meridian terylene and latitudinal polyamide fiber. It has advantages of short tensile, stable size good elasticity, shock resistant, heat resistant mould-resistant, high adhesive strength. It is applicable to convey material in medium and long distance, with heavy-load and at high speed.

2. Heat Resistant Conveyor Belt

Applicable

Metallurgy, Cement Plant, Fertilizer, And High-temperature Environment.

Features

Special rubberized fabric instead of common fabric.

Note:

1.There is very difference temperature between materials with surface of belt.

2.The above difference come form materials conveyed size,cooling(water,ventilation,ect)

3. Chemical Resistant Conveyor Belt

Applicable

Chemical plant,chemical fertilizer plant,paper-marking factory.

Features

1. As the belt core consists of cotton-duck, nylon-duck or EP-duck, the belt has good features elasticity, excellent troughability, and low elongation.

2. The rubber cover, made of chemical resistant materials, has good anti-chemical corrosive and physical performance.

Technical indexes

Physical property of rubber under hot air accelerated aging test(test condition: 50°C*96h).

4. Flame Resistant Conveyor Belt

Applicable

It is suitable for conveying various non-corrosive and thornless materials in blocks, in grains, in grains, or in powder, such as coal in bulk or in bales, under the condition of flammable or explosive environment above coalmine wells.

Features

The product is made of cotton canvas, nylon canvas or EP canvas and finisher through the processes of calendaring, assembling, vulcanizing ect.

5. Cold Resistant Conveyor Belt

Applicable

1. Refrigeration plant and high latitude area.

2. It is suitable for conveying materials outdoors in freezing area, cold storage and etc.

3. The cold-resistant conveying belt is divided into two classes, C1 and C2: C1 class belt is applicable to environment temperature from -45-+50°C; and C2 class belt is -60-+50°C.

Features

1. The product selects cotton canvas, nylon canvas or EP canvas as carcass.

2. Cover rubber selects a blend of NR and BR, witch has the properties of high elasticity, shock resistance, cold resistance and etc. It can work normally under the conditions of -60°C